Custom Architectural Millwork

When you walk into a home that feels substantial, grounded, and undeniably high-end, you aren’t just reacting to the furniture or the layout. You are reacting to the architecture itself.

For centuries, architectural millwork—wainscoting, coffered ceilings, complex moldings, and built-in cabinetry—has been the bridge between a house’s structure and its inhabitants. It transforms a drywall “box” into a home with history and character.

At Choice Custom Cabinetry & Design, we believe that true luxury is not about ornamentation; it is about precision, material knowledge, and the “why” behind every cut. This guide is designed for homeowners, architects, and builders who want to understand the mechanics, biology, and artistry of custom woodwork.

The Biology of Wood (Why “Custom” Matters)

Before we discuss design, we must discuss the medium. Wood is a living material, even after it has been harvested. It breathes, moves, expands, and contracts.

The Myth of “Stable” Wood

One of the most common failures in mass-produced millwork is the neglect of local acclimation. Wood is hygroscopic—it absorbs and releases moisture based on the relative humidity of its environment.

- The Risk: If millwork is manufactured in a dry climate (like overseas factories) and installed in the humid summers of Pennsylvania or New Jersey, the wood will swell. Joints will crack, paint will fracture, and doors will bind.

- The Solution: Sourcing and manufacturing locally. In our Honey Brook shop, we work with lumber that has been acclimated to the Northeast’s climate. We mill the wood to a specific moisture content (typically 6-8%) that ensures stability in your specific home.

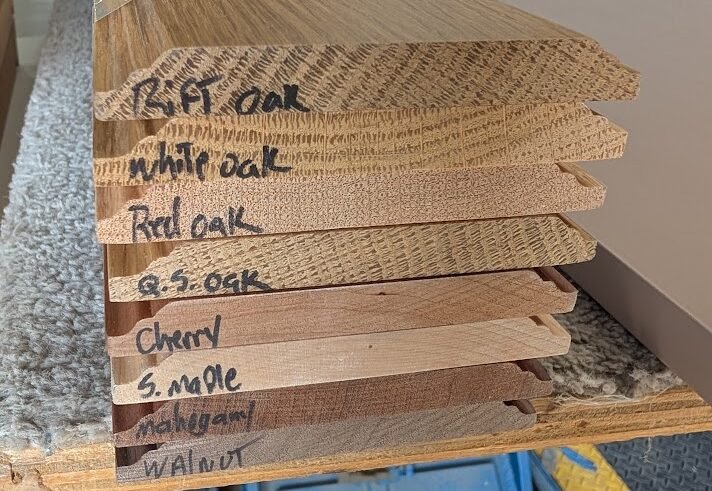

The Cut Matters: Plain Sawn vs. Rift Sawn

Why does some oak look “busy” and cheap, while other oak looks linear and modern? It comes down to how the log is sliced.

- Plain Sawn (Flat Sawn): The most common and cheapest cut. The grain creates “cathedrals” or arches. While traditional, it is less stable and more prone to cupping.

- Quarter Sawn: The log is cut into quarters first. This produces a straight grain with distinctive “flecks” (medullary rays). It is significantly more stable than plain sawn.

- Rift Sawn (The Architect’s Choice): The most wasteful but most stable cut. The log is milled perpendicular to the growth rings. The result is a tight, straight linear grain without the “flecks.”

- Expert Note: For modern clean lines or high-end transitional designs, we almost exclusively recommend Rift Sawn White Oak. It provides texture without visual chaos and offers the highest dimensional stability.

The Elements of Architectural Millwork

Millwork serves three functions: protection, proportion, and aesthetic.

1. Wainscoting and Wall Paneling

Historically, wainscoting was used to protect the lower half of plaster walls from dampness and damage (chair backs, boots, etc.). Today, it is a tool for visual scaling.

- The Rule of Thirds: Visually, a wall looks best when divided into thirds. Wainscoting should typically sit at 1/3 of the wall height (chair rail height) or 2/3 (plate rail height).

- Panel Styles & When to Use Them:

- Raised Panel: Formal, traditional, creates deep shadows. Best for libraries and formal dining rooms.

- Recessed Panel (Shaker): Clean, transitional. Works in almost any setting.

- Board and Batten: Rustic or Craftsman. Vertical lines make a ceiling feel higher.

- The “Stile & Rail” Construction: True custom wainscoting is built using stile and rail construction (like a door), not just molding glued to drywall. This allows the wood panels to “float” within the frame, expanding and contracting with the seasons without cracking the paint.

2. Coffered and Beamed Ceilings

The ceiling is often called the “fifth wall.” Treating it can change the acoustics and the psychological feel of a room.

- Acoustics: A large, flat drywall ceiling reflects sound, creating echoes. A coffered ceiling (a grid of sunken panels) acts as a baffle, breaking up sound waves and making a large room feel quieter and more intimate.

- The Engineering Challenge: Real solid wood beams are heavy. In our shop, we often fabricate “box beams”—hollow structures made from 3/4” hardwood with lock-mitered joints.

- Benefit: They look indistinguishable from solid timber but are lighter (safer for your roof structure) and allow us to run electrical wiring or recessed lighting inside the beam itself.

3. Built-In Cabinetry (Libraries & Offices)

Unlike a kitchen, which is strictly functional, a library or study is experiential.

- Integration: High-end millwork shouldn’t look like furniture pushed against a wall; it should look like part of the wall. This requires scribing—the process of shaping the edge of the cabinet to match the subtle irregularities of your floors and walls perfectly.

- Sequence Matching: For stained wood libraries (Walnut, Cherry, Mahogany), we use “sequence matched” veneers. This means the grain pattern continues seamlessly from one cabinet door to the next, like a flowing river. You cannot achieve this with factory-made cabinets.

The Amish Manufacturing Advantage

Why do architects specify “Amish-made” or “Local Craftsmanship” on blueprints? It is not just about nostalgia; it is about engineering.

Mortise and Tenon Joinery

Mass production relies on dowels, staples, or cam-locks to hold wood together. These are mechanical connections that loosen over time as wood vibrates and moves. In our shop, we utilize Mortise and Tenon joinery. One piece of wood (the tenon) is shaped to fit inside a hole cut into the other piece (the mortise). Glued together, this creates a bond stronger than the wood itself because it maximizes surface area for the glue.

The Finishing Process: Chemistry Meets Art

The difference between a “good” cabinet and a “luxury” cabinet is usually the finish. You can have the best joinery in the world, but a poor finish will fail in five years.

- Conversion Varnish vs. Lacquer: Many commercial shops use nitrocellulose lacquer because it dries fast. However, it is brittle and susceptible to moisture (the “white ring” from a water glass).

- Our Standard: We use catalyzed Conversion Varnish (CV). It is chemically hardened. Once cured, it is impervious to water, alcohol, and most household chemicals. It provides the “feel” of silk but the durability of a countertop.

When to Choose Custom vs. Semi-Custom?

At Choice Custom Cabinetry, we offer both. Honesty is part of our business model, so here is a transparent breakdown of where you should invest your budget.

When to Invest in Full Custom Millwork:

- Historic Restoration: If you own a home built in 1890, standard moldings will look alien. We can grind custom knives to match your existing profiles exactly.

- Odd Dimensions: Philadelphia rowhomes and historic farmhouses rarely have 90-degree angles or standard widths. Custom work is built to fit your space, not the other way around.

- The “Wow” Factor Areas: Kitchens, Master Suites, and Main Libraries. These are the areas that drive the value of the home. Using Rift Sawn White Oak or sequence-matched Walnut here offers a high ROI (Return on Investment).

- Specific Color/Finish: When you need to match a specific fabric in a rug or an heirloom piece of furniture.

When Semi-Custom is the Smart Choice:

- Laundry Rooms & Mudrooms: These are high-wear, utilitarian spaces. Our Semi-Custom line offers durability and any Sherwin-Williams color without the cost of bespoke engineering.

- Guest Baths & Secondary Bedrooms: Standard sizes often work perfectly here.

- Rental Properties: You need durability and speed, but perhaps not “sequence matched walnut.”

The Value of “Locally Made”

In the era of global supply chains, there is a tangible value to local manufacturing in Pennsylvania.

- Supply Chain Security: We source our lumber domestically. We are not waiting for a shipping container from overseas to finish your project.

- Serviceability: If a door gets scratched by the movers or a dog chews a piece of trim five years from now, you can call us. We have your file, we know your finish formula, and we can make a replacement part.

- Collaboration: You (or your architect) can visit our Honey Brook factory. You can touch the raw wood before it is finished. You can verify the stain sample under the actual lighting conditions of your home, not just in a catalog.

Building for the Next Generation

Architectural millwork is an investment in the permanence of a home. It is the difference between “decorating” a space and “building” one.

Whether you are an architect looking for a partner who speaks your language of details and specs, or a homeowner ready to transform a room into a legacy, Choice Custom Cabinetry & Design is ready to execute your vision.

Ready to Start Your Project?